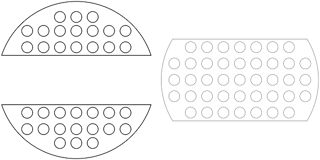

In AHED release 3.2.17.729 we have added the possibility to calculate with double segmental baffles. These baffles split the shell side flow in two currents around each second baffle. This way a reduction in velocity is obtained. In general, this will lead to a reduction in pressure drop and a reduced vibrational risk. The next image shows the principle of double segmental baffles and how they split the flow around a baffle that is placed in the centre. The next baffle consists of two outer segments where the two currents are joined again in a central window.

The reduction in flow velocity influences the rate of heat transfer. Normally, heat transfer is increased less with double segmental baffles then with single segmental baffles. But in general, double segmental baffles will give an improvement over a design with zero or very few baffles.

Double segmental baffles must be designed with a small overlap between the centre baffle and the split baffle. This overlap must be large enough to house a minimum of one tube row. Because of this requisite, double segmental baffles will be less useful with small tube bundles and work better with larger ones.

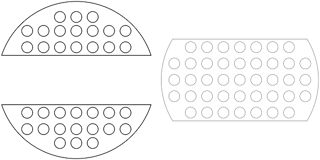

In AHED you will find a drop-down box where you choose between single segmental and double segmental baffles:

The Central Baffle Cut parameter defines the opening (in % of shell diameter) around the centre baffle. The Side Baffle Cut parameter defines the opening (in % of shell diameter) of the space confined between the baffles that has two segments. From this definition it should be clear that any cut >= 50% will not allow for any overlap between the two baffles and an error will inform you of this. The overlap parameter indicates the overlap distance in mm. Use this value as a guide in the design process.

Double segmental baffles should always be designed with un uneven number of baffles. The first and last baffle must be a split baffle. This avoids preferential flows at the shell side inlet and outlet position.

Try to work with the double segmental option for cases where single segmental fail to give a workable solution. Where a lot of single segmental baffles can give an excessive pressure drop, double segmental baffles can provide the alternative.